While I acknowledge the expectations Ellis tries to set, all the youtubers out there have me chasing a dragon looking for better and better layer aliment on my z-axis. I suspect (at least) one of you will come out of the woodwork and say your printer has better aligned layers than mine too 😭 I’m certainly not alone, but even in that thread you can find some people claiming that not everyone experiences the issue

So far, I’ve been through three iterations on my CW2:

- BMG gears with a grub screw

- BMG Integrated Drive Gear Assembly (IDGA). Press fit gear = no more grub screw

- FYSETC CNC Pom w/ Helical gears, since evidently the BMG gears can still be somewhat offset

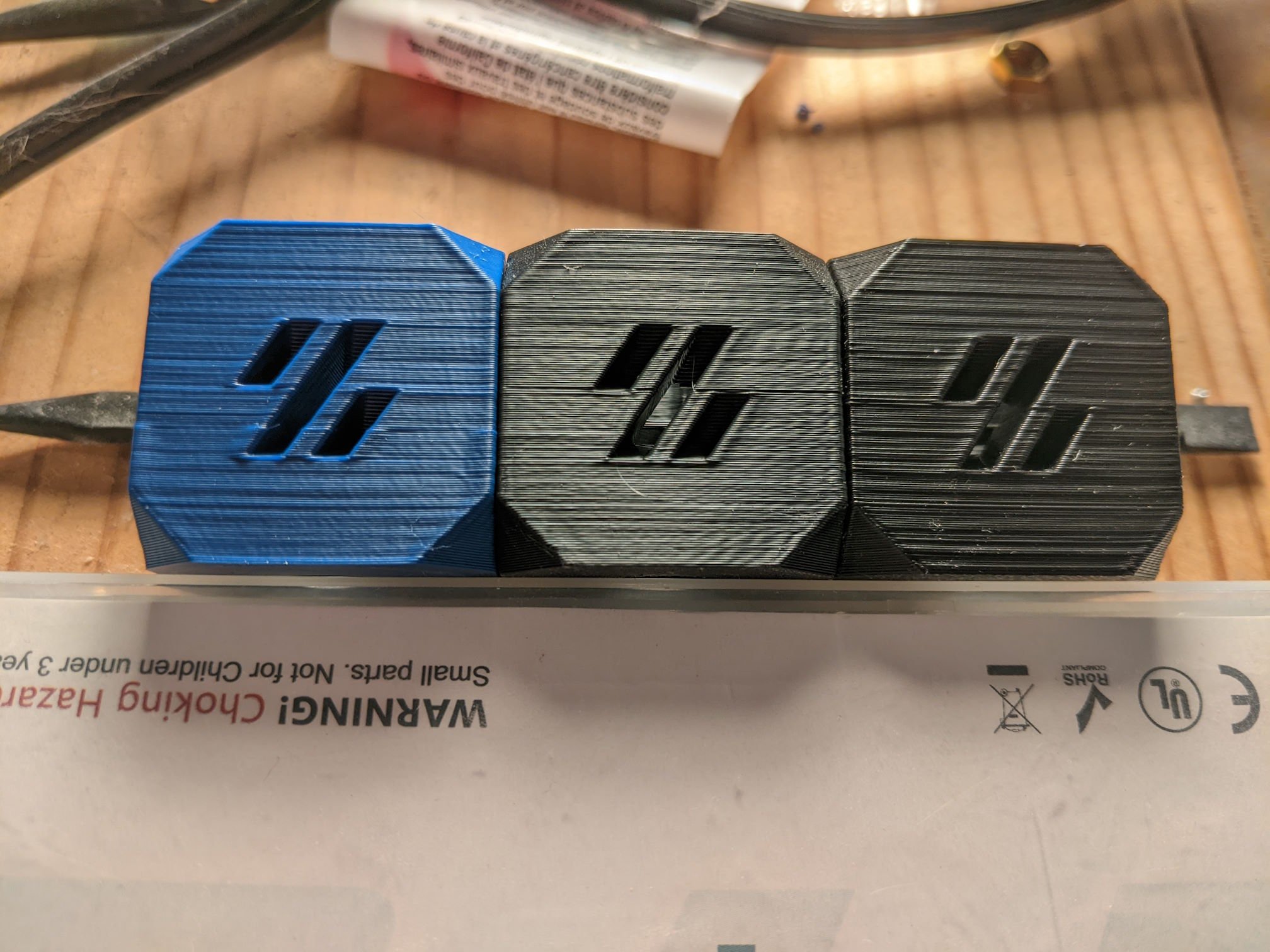

Results below with me hand holding my cellphone and moving a Pixar style desk lamp to be at a progressively steeper angle to the face of the cubes. Left = FYSTEC Pom (I also used Orcaslicer), middle = BMG IDGA, right = ‘normal’ BMGs. Note that the cubes are upside down.

Vanity shot with very soft and indirect light

Direct light, 90 degrees to the face of the cubes (basically perpendicular)

Direct light, ~45 degrees to the face of the cubes

Direct light, ~5 degrees to the face of the cubes (basically parallel)

At this point, I am going to shrug, give up, and print with fuzz (or avoid harsh light).

What do you mean? The quality of the cubes themselves or the surface finish? There is a bit of skin defect going on and it looks like OrcaSlicer introduced some corner rounding about 1/3 of the way up the blue cube. I still need to run input shaper, but the prints don’t seem that bad? Maybe my standards are low s because of the absolutely appalling quality of my old I3 clone.

This is also intentionally pretty harsh lighting. I just added the OP to add a photo with more diffuse lighting and all three prints look way more like what you’ll find on the web.

The inserts are poorly inserted and into oblongated & incorrect ID (too big) holes, and the print quality looks poor (just low quality printer likely). Doubt those shafts are perpendicular or located accurately. But I’m not looking at this from a hobbyist perspective, but from a mechanical engineer, machine designer perspective.

Cheap printers are a waste of time IMO, but a good engineering learning experience

Thank you for the more detailed reply. The part in question is is a Voron Design Cube. I printed it on my 350mm Voron 2.4. The print does match the source STL fairly well, but it does look like OrcaSlicer’s result (blue) has more corner rounding than the SuperSlicer results. There’s a 45 degree chamfer on both the lower and upper face of the Z, which might contribute to what you’re seeing. The parts themselves are also physically not that large, so you might be seeing a bit of the impact of the nozzle being round too.